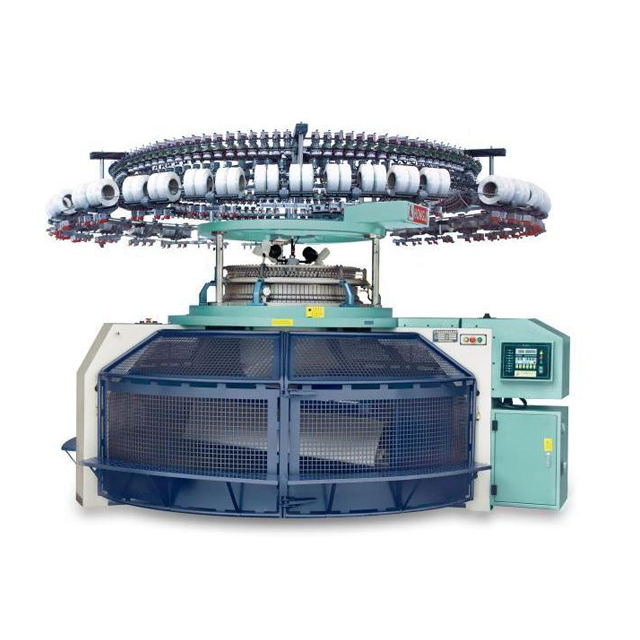

Based on combination of the knitting principle with human engineering and aesthetics the machine has a smart appearance and solid structure. Whole machine adopts high-class cast iron to avoid deformation of machine parts through timing effect under long-term natural or artifical conditions, which results in long useful time and outstanding production performance. Applications of CNC machining center and special surface heat treatment lead to reliable long-term running and durable machine parts. The transmission mechanism adopts wire-race bearing from Germany which enhances running precision and reduces noise and energy loss, and durable years of the machine is therefore profited. The tolerance of the latest central adjustment device is less than 0.03mm, which ensures the accuracy when up and down, and makes spacing of weight adjustment finer, loops clearer and more consistent, and accordingly, fabrics are endued with better hand-touch feeling.

Area of Application

The high speed four-needle race single jersey knitting machine series with cutting cloth function is developed according to the high speed single knitting machine and large-scale opening and rolling machine, which not only bears the advantages of high speed single jersey knitting machine, but also outputs the fabric without folding mark, thus leading to decrease of the production cost, increase of the profit and full use of the material. The socket piped batching rail can be drawn out easily after batching. Meanwhile, the machine can stop automatically when the piece is cut incompletely due to the safety stop motion. The high-quality silk and high density knitting fabric can be made on this machine, and also it is a best choice for the stretch cloth.

| SIZE | 26-38 inch 3F/inch 4F/inch | GUAGE | 1G6-50G |

| NEEDLE | 104/141 | STYLES | Regular/open width/high feet/openwidth-high feet |